The construction and heavy lifting industry has evolved, and large hydraulic cranes are at the forefront of this transformation. According to recent reports, the global crane market is expected to reach over $45 billion by 2026, propelled by booming infrastructure projects. Large hydraulic cranes play a crucial role in this growth, providing efficiency and reliability for heavy lifting solutions.

In 2026, selecting the right large hydraulic crane model will be paramount. Companies are investing in advanced models that offer increased lifting capacities and greater precision. Data shows that cranes equipped with smart technology can increase productivity by up to 25%. Yet, it’s not just about functionality. Safety remains a significant concern, as the industry grapples with numerous reported incidents. This calls for a critical evaluation of crane handling practices and operator training.

As we explore the best large hydraulic crane models for heavy lifting, we must consider both their capabilities and limitations. Not all models are created equal. Factors such as load weight, lift height, and operational terrain will impact their effectiveness. The inner workings of each model merit close inspection to ensure they meet specific project needs. Thus, thoughtful analysis is essential in navigating the choices available in 2026.

Large hydraulic cranes are vital for heavy lifting in construction and industry. In 2026, these cranes have evolved significantly. They now incorporate advanced hydraulic systems that improve lifting capacity. Operators can manage loads effectively, reducing the risk of accidents. The design focuses on stability and mobility, crucial for complex job sites.

The latest models are equipped with smart technology. Sensors monitor weight and balance in real time. Many cranes can make adjustments automatically. However, the reliance on technology raises concerns. Not all operators are familiar with these systems. Some may prefer traditional controls. Training remains essential to minimize errors. Users must adapt to new capabilities and ensure compliance.

Maintenance is another area requiring attention. Regular servicing is crucial to uphold performance. Neglecting maintenance leads to breakdowns, causing delays. Ultimately, the balance between innovation and practicality is key. While modern features provide advantages, they also require careful management. Only then can large hydraulic cranes truly excel in heavy lifting solutions.

| Model | Max Load Capacity (tons) | Boom Length (meters) | Operating Weight (tons) | Fuel Type | Year Launched |

|---|---|---|---|---|---|

| Model A | 500 | 60 | 150 | Diesel | 2026 |

| Model B | 600 | 65 | 180 | Diesel | 2026 |

| Model C | 700 | 70 | 210 | Electric | 2026 |

| Model D | 800 | 75 | 220 | Hybrid | 2026 |

| Model E | 900 | 80 | 250 | Diesel | 2026 |

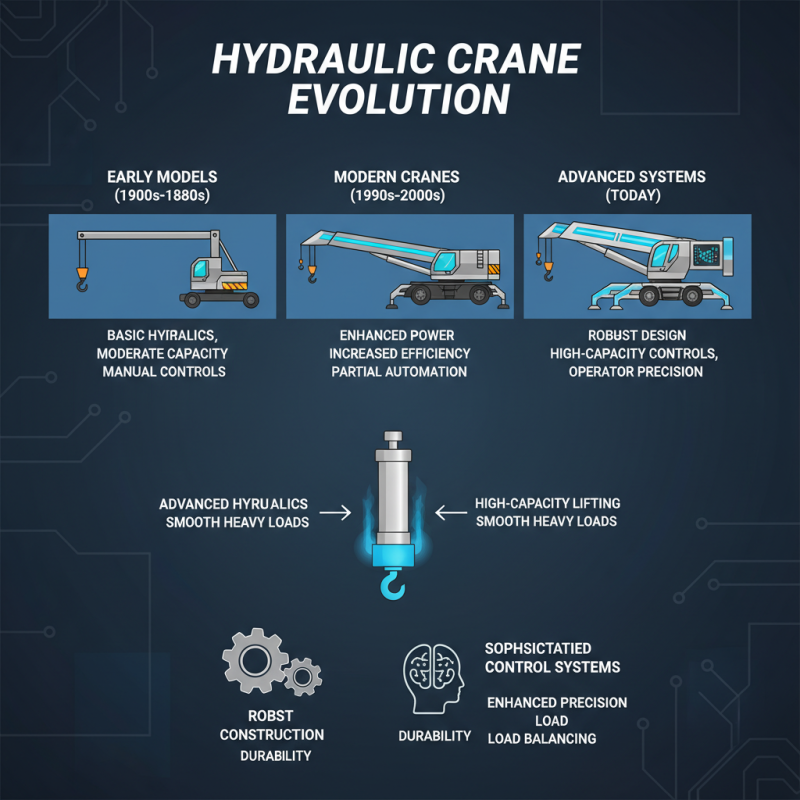

Hydraulic cranes have evolved significantly. Their design focuses on increased lifting capacity and efficiency. Modern models often combine robust construction with advanced hydraulics. This allows for smooth operations under heavy loads. Many cranes now utilize sophisticated control systems, enhancing operator precision. Operators can anticipate and counterbalance heavy loads much more effectively.

Technology plays a key role in these cranes. Many incorporate sensors to provide real-time data. This ensures safety and improves decision-making. However, not every crane maximizes these features. Some models may lack necessary updates, leading to inefficiencies. Resolving these issues requires diligent maintenance and checks. Operators must remain vigilant to harness the full potential of their equipment.

The best hydraulic cranes of 2026 also focus on sustainability. They are often built with eco-friendly materials. Energy-efficient engines reduce emissions during operation. Nonetheless, some designs might still struggle with weight distribution. Improving stability remains a challenge for manufacturers. Understanding and addressing these shortcomings will define the future of hydraulic crane technology.

Hydraulic cranes have become essential in heavy lifting applications. They are designed for efficiency and power. According to a recent report by the International Construction Market, the demand for hydraulic cranes is projected to grow by 5% annually until 2026. This growth reflects the need for advanced lifting solutions in various industries.

Key features include lifting capacities of up to 800 tons. Operators can handle heavy loads safely and efficiently. New models focus on enhancing stability and control. Many cranes come with advanced hydraulic systems that ensure smoother operations. However, challenges remain. Maintenance is vital for optimal performance. Neglect can lead to unexpected downtime and costly repairs.

Operator training is crucial. Skilled personnel can maximize the capabilities of each model. Inadequate training may lead to accidents and productivity losses. Therefore, companies must invest in both equipment and personnel. Balancing innovation with safety remains a challenge in the industry. It’s a continuous effort to improve both technology and operator skills.

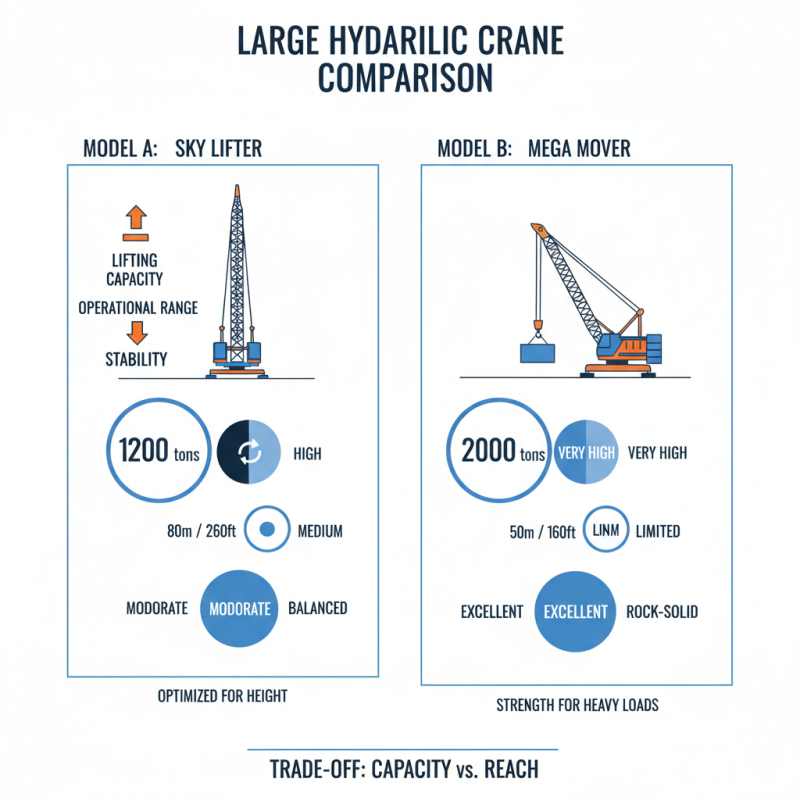

When comparing large hydraulic crane models, performance metrics are crucial. Focus areas include lifting capacity, operational range, and stability. Models vary significantly in these aspects. Some excel in maximum height but struggle with heavy loads. Others manage weight well but have limited reach. This trade-off can impact project efficiency.

Stability is another critical metric. Some cranes are more robust than others, especially on uneven terrain. A crane's ability to maintain balance under heavy loads is essential for safety. Users must assess specific job site conditions before choosing a model.

Fuel efficiency remains a concern as well. Some models consume more fuel, leading to higher operational costs. Tracking fuel usage helps in evaluating long-term investments. Each crane's unique features may provide advantages, but careful analysis is needed. Performance must be matched with real-world application. All choices have their trade-offs. Make informed decisions for the best outcomes.

The future of hydraulic crane design emphasizes efficiency and mobility. The global hydraulic crane market is expected to reach $18 billion by 2026, driven by the demand for heavy lifting solutions across industries. Increased urbanization creates a need for cranes that can maneuver in tight spaces. Manufacturers are focusing on compact designs while ensuring powerful lifting capabilities.

Sustainability is another critical trend. Hydraulic cranes are adopting eco-friendly technologies. Research indicates that cranes with hybrid engines can reduce fuel consumption by up to 30%. This is essential as regulations tighten around emissions. Operators may face challenges integrating these new systems. Training is vital to maximize the effectiveness of these advanced machines.

Smart technology is infiltrating hydraulic crane designs. Remote control and automation features are becoming standard. However, reliance on technology can introduce risks. Technical failures may occur, and operators must remain alert. Regular maintenance and training are essential to mitigate these issues. Balancing innovation with human oversight will be crucial in the coming years.