The construction industry relies heavily on safe and efficient equipment. A certified crane is critical for any project. In recent years, the demand for certified cranes has increased by over 25%, according to industry reports. This growth follows rising construction needs and infrastructure development.

Choosing the right certified crane can be daunting. Many models exist, each with unique specifications. Not every option is suitable for every construction type. Project managers often struggle to balance price, performance, and safety records. Safety is paramount; cranes accounted for 24% of all construction-related fatalities in 2022, emphasizing the need for certified options.

To ensure success, contractors must focus on quality. Relying solely on cost can lead to unforeseen issues. Investing in a certified crane reduces risks and enhances productivity. The right model can significantly impact project timelines. As the industry pushes towards modernization, understanding certified crane features becomes essential. Ignoring this could lead to setbacks and financial loss.

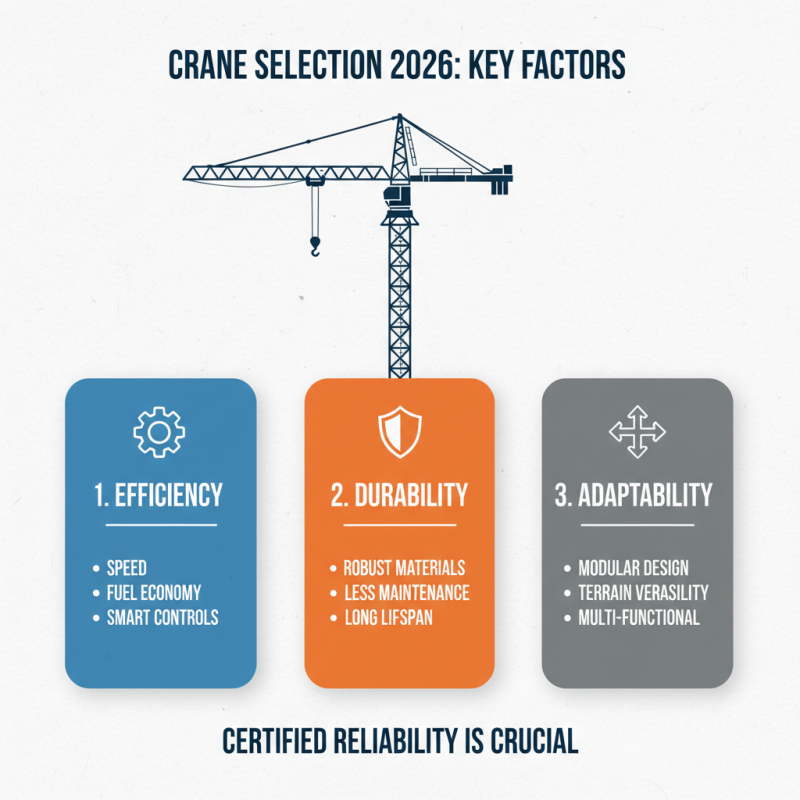

When choosing a certified crane model for construction in 2026, several factors come into play. The demands of modern construction require versatile equipment. Cranes must be efficient, durable, and adaptable to various job sites. Many models offer unique features, but their reliability is crucial.

The latest crane models prioritize safety and functionality. They come with advanced technology for better precision during lifts. Operators often report that intuitive controls improve their workflow. However, workers still face challenges in training and certification processes. Misunderstandings about operating procedures can lead to potential risks on site.

Construction teams also seek cranes that can handle heavy loads while being easy to maneuver. Many operators prefer models that provide a good balance between power and stability. Yet, balancing these attributes can be difficult. Models that excel in one area may fall short in another. It's vital to reflect on these trade-offs to make informed decisions.

When selecting a construction crane, certain key features are paramount. Load capacity is a crucial factor. Ensure the crane can handle the weight of your materials. Consider the reach as well. It should extend far enough for your specific site requirements. Stability is essential too. A crane that sways is a disaster waiting to happen.

Height and lift speed can greatly impact productivity. A crane that operates swiftly can save time on projects. Secure controls and user-friendly interfaces also enhance safety. The last thing you want is confusion during operation. In some cases, smaller cranes can perform just as well if they meet your basic needs.

Many overlook maintenance needs. A good crane should have easily accessible parts for servicing. This can avoid delays due to breakdowns. Don't forget about your operator's comfort. Efficient cranes often require skilled drivers. If they're uncomfortable, it could affect their performance. Addressing these points early can save you time and money later.

As construction demands evolve, choosing the right crane becomes crucial. In 2026, contractors need cranes that combine efficiency and versatility. Many construction sites require heavy lifting capabilities. Therefore, selecting a top-rated crane is essential for project success.

Some cranes excel in urban environments. They can navigate tight spaces while lifting heavy loads. However, not all cranes perform well in every scenario. Weather conditions can impact their performance. If operators are inexperienced, it can lead to accidents. Training is key, but even trained professionals can underestimate challenges.

Additionally, maintenance plays a significant role. Regular checks can prevent breakdowns during critical phases. Yet, some construction teams overlook this. Such negligence can delay projects and increase costs. It's important to reflect on these aspects when investing in cranes. Balancing power and safety is the ultimate goal.

When evaluating cranes for construction, various brands offer distinct features tailored to different needs. Some models excel in

lifting capacity, while others may have superior maneuverability. It’s important to assess the specific requirements of your project. An analysis of specifications can reveal which options are better suited. There may be trade-offs between power and precision.

Consider the durability of materials used in construction. Some cranes are built to withstand harsh environments. Weather conditions can impact performance. Reliability becomes key during critical operations. Additionally, user interfaces differ significantly across models. A more intuitive control system may reduce the learning curve for operators.

In practical terms, maintenance should be a consideration. Some models may require more regular servicing than others. This can affect overall project timelines. It's also prudent to reflect on feedback from operators who have experience with various cranes. Their insights can shed light on practical performance, highlighting both strengths and limitations. Investing time in comparisons can save money and prevent future challenges.

In the construction industry, certified cranes play a vital role. They are essential for lifting heavy materials and ensuring site efficiency. However, safety standards are critical. Compliance with regulations is non-negotiable. Every project must prioritize the safety of workers and the public. Relying on certified models helps minimize risks.

Regular inspections of cranes are necessary. These checks ensure that machinery functions correctly and adheres to safety protocols. Operators must be trained and certified. Their expertise directly impacts safety on the site. Construction companies sometimes overlook training. This can lead to accidents and costly delays.

Documentation is important in maintaining compliance. Keep records of inspections, certifications, and operator training. Follow-up on any identified deficiencies immediately. Reflecting on these practices can reveal gaps in safety measures. Awareness and continuous improvement are essential for a safe working environment.