In the world of construction and heavy lifting, the techniques used for rigging and crane operations are pivotal for ensuring safety and efficiency. Mastering the best practices in rigging and crane techniques not only minimizes risks but also enhances productivity on job sites. As heavy machinery and loads become integral to various industries, understanding the critical aspects of rigging and crane work is vital for all professionals involved. With the right methods in place, workers can navigate complex lifting scenarios with confidence and precision.

This article will explore the top ten rigging and crane techniques that are essential for any lifting operation. Each technique has been carefully selected based on its effectiveness and contribution to maintaining a secure working environment. From understanding the fundamentals of load calculations to mastering the nuances of rigging setups, these techniques serve as a foundation for successful operation. Whether you are a novice or an experienced operator, these guidelines will provide valuable insights into optimizing your rigging and crane activities. By implementing these best practices, teams can foster a culture of safety while improving overall operational efficiency.

Understanding the basics of rigging is essential for safe lifting operations in any construction or industrial environment. Effective rigging techniques not only ensure the safety of personnel but also prolong the lifespan of the equipment being utilized. According to the Occupational Safety and Health Administration (OSHA), improper rigging practices contribute to a significant percentage of workplace accidents, costing companies thousands of dollars in downtime and injuries. By mastering essential rigging principles, operators can mitigate risks while optimizing the efficiency of lifting operations.

Rigging encompasses various fundamental concepts, including the selection of appropriate gear, understanding load weight limits, and dynamic load considerations. Industry reports indicate that approximately 70% of rigging-related accidents stem from equipment failure due to overloading or improper setup. Operators must be well-versed in calculating the safe working load (SWL) of the rigging equipment and considering factors such as weather conditions and load stability. This knowledge lays a foundation for creating safer work environments and enhances overall operational efficiency, which is vital in industries where time and safety are of the essence.

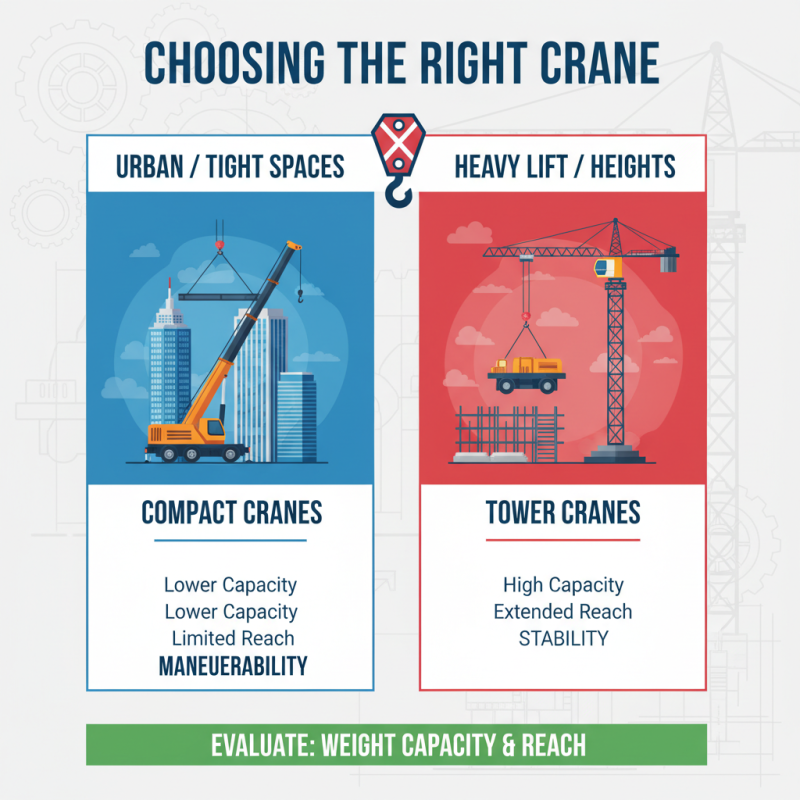

When selecting the right crane for your lifting needs, it's essential to first evaluate the specific requirements of your project. Different cranes are designed to handle varying weights, reach distances, and types of loads. For instance, if you're working in a tight urban environment with restrictions on space, a compact crane might be more appropriate. Conversely, if your task involves lifting heavy machinery or materials over a significant height, a tower crane could be the ideal choice. Ensure you assess the weight capacity and reach of the crane to match it with the nature of your lifting operations.

Additionally, understanding the operational environment is crucial in guiding your selection. Factors such as ground stability, overhead obstructions, and nearby structures can significantly impact your crane's performance and safety. It's also important to consider the ease of setup and transportation for the crane. Some cranes may require more complex assembly procedures or specialized crews, which can affect both time and costs. By aligning the crane's features with your project's demands and the environment, you can ensure a safe and efficient lifting operation.

When it comes to rigging, achieving load stability and safety is paramount. Proper techniques not only ensure the security of the load but also protect the crew handling it. One essential technique is to always assess the load's center of gravity before lifting. Understanding this balance point allows for more controlled movements and reduces the risk of tipping or swaying.

Tips: Always mark the center of gravity clearly on the load to provide a visual reference for the rigging crew, which aids in a collective understanding of how to manage the load.

Another critical aspect is the use of appropriate rigging gear. Selecting slings and attachments based on the load type and weight is vital. For instance, using the right sling angle minimizes stress and maximizes lifting capacity.

Tips: Regularly inspect rigging equipment for wear and damage before use, ensuring that all components meet safety standards. Consistent maintenance can prevent accidents and enhance overall efficiency during lifting tasks.

When it comes to crane operation and load handling, adhering to best practices is crucial for ensuring safety and efficiency on job sites. One of the fundamental practices is conducting thorough pre-lift inspections. Operators must assess the crane's condition and all rigging equipment, checking for any signs of wear or damage. This proactive approach not only helps in identifying potential issues before they escalate but also builds a safety culture among workers.

Another essential aspect of safe load handling is understanding load dynamics and weight distribution. Operators should be trained to calculate the center of gravity of the load, allowing for proper rigging techniques. Utilizing the correct rigging gear, including slings, chains, and shackles, is vital to secure loads effectively. It is also important for operators to communicate clearly with their team members, utilizing hand signals or radios to ensure that everyone is aware of the plan and any changes during the operation. By following these practices, crane operations can be managed safely while minimizing the risk of accidents.

| Technique | Description | Safety Tips | Efficiency Impact |

|---|---|---|---|

| Load Assessment | Evaluate the weight and dimensions of the load before lifting. | Use scales or measuring tools to determine load weight accurately. | Improves planning and reduces the risk of overloading. |

| Proper Rigging | Select and attach rigging equipment suitable for the load. | Check for wear and damage on rigging equipment. | Increases load stability during lifting. |

| Clear Communication | Ensure all team members understand hand signals and commands. | Conduct a pre-lift meeting to clarify roles. | Enhances coordination and reduces mistakes. |

| Boom Angle Adjustment | Adjust the boom angle for optimal lifting position. | Avoid exceeding the rated load capacity at various angles. | Maximizes lifting efficiency and load control. |

| Regular Equipment Inspection | Conduct routine checks on cranes and rigging gear. | Ensure certification is up to date. | Reduces breakdowns and unscheduled downtime. |

| Use of Tag Lines | Employ tag lines to control the load while lifting. | Keep tag lines away from the load path. | Enhances safety and stability during movement. |

| Load Swing Control | Minimize load swing by starting and stopping slowly. | Anticipate braking distances to prevent sudden movements. | Improves accuracy in positioning loads. |

| Emergency Procedures | Establish emergency protocols for incidents during lifting. | Practice emergency drills regularly. | Ensures quick response to unexpected situations. |

| Operator Training | Ensure all operators are trained and certified. | Update training regularly to include new safety practices. | Increases operator confidence and reduces accidents. |

In the rigging and crane industry, safety measures and regulations play a pivotal role in ensuring both operational efficiency and the prevention of accidents. According to the Occupational Safety and Health Administration (OSHA), over 4,500 workplace fatalities occur each year in the United States, with a significant percentage attributed to improper lifting practices. To combat this, organizations are encouraged to adhere strictly to established guidelines, which include regular inspections of equipment and comprehensive training for personnel involved in lifting operations.

Implementing a robust safety training program is crucial. This should cover the use of personal protective equipment (PPE), load calculations, and the proper signaling methods for crane operators. It's imperative that all workers are familiar with these regulations, as the National Safety Council reports that effective safety programs can reduce workplace injuries by up to 70%. Ensuring thorough training not only fosters a culture of safety but also enhances overall performance and productivity in lifting operations.

**Tip:** Always perform a pre-lift meeting with your team to discuss the specific lift plan, potential hazards, and emergency procedures. This collaborative approach helps to reinforce everyone's understanding of safety protocols.

Moreover, keeping an eye on weather conditions can significantly impact safe rigging and lifting practices. Wind speeds exceeding 20 mph, for instance, can pose risks during crane operations. Regularly consulting weather forecasts and maintaining communication with the crane operator during adverse conditions can mitigate risks.

**Tip:** Establish a designated safety officer who can monitor environmental conditions and make real-time decisions about lifting operations based on these factors.