Choosing the right model for your Mcdal crane needs is a critical decision that can significantly impact operational efficiency and project outcomes. According to a recent industry report by the Crane Manufacturers Association of America, the construction and lifting equipment market is projected to grow by 5.6% annually through 2025. This growth underscores the importance of selecting the right equipment to meet specific operational demands.

Industry expert John Smith, a noted authority on crane applications, emphasizes the importance of making informed choices: "Selecting the appropriate Mcdal crane model is not just about capacity; it’s about matching the crane's capabilities with the unique requirements of each project." This statement highlights the need to consider factors such as lifting height, weight capacity, and environmental conditions when choosing a Mcdal crane. Tailoring your selection to these elements can lead to enhanced safety and productivity on the job site.

As the industry evolves with advancements in technology and changing operational needs, understanding the nuances of Mcdal crane models becomes increasingly important. By investing time in research and analysis, businesses can ensure they are equipped with the best tools to meet their lifting and construction challenges.

When selecting the right model for your Mcdal crane needs, it's crucial to first understand the different types of cranes available on the market. Mcdal cranes come in various configurations, each designed for specific applications and environments. For instance, mobile cranes offer portability and flexibility, making them ideal for construction sites that require frequent relocation. On the other hand, tower cranes provide impressive lifting capabilities and precision, often employed in tall building projects where height and stability are paramount.

Another key type to consider is the crawler crane, which is equipped with tracks instead of wheels. This design allows for enhanced stability and weight distribution, making them suitable for rough terrains or heavy lifting tasks. Additionally, there are all-terrain cranes that combine the features of both mobile and rough-terrain cranes, offering versatility in navigating different surfaces while maintaining lifting power. By understanding these various types of Mcdal cranes, you can make a well-informed decision that aligns with your specific operational requirements.

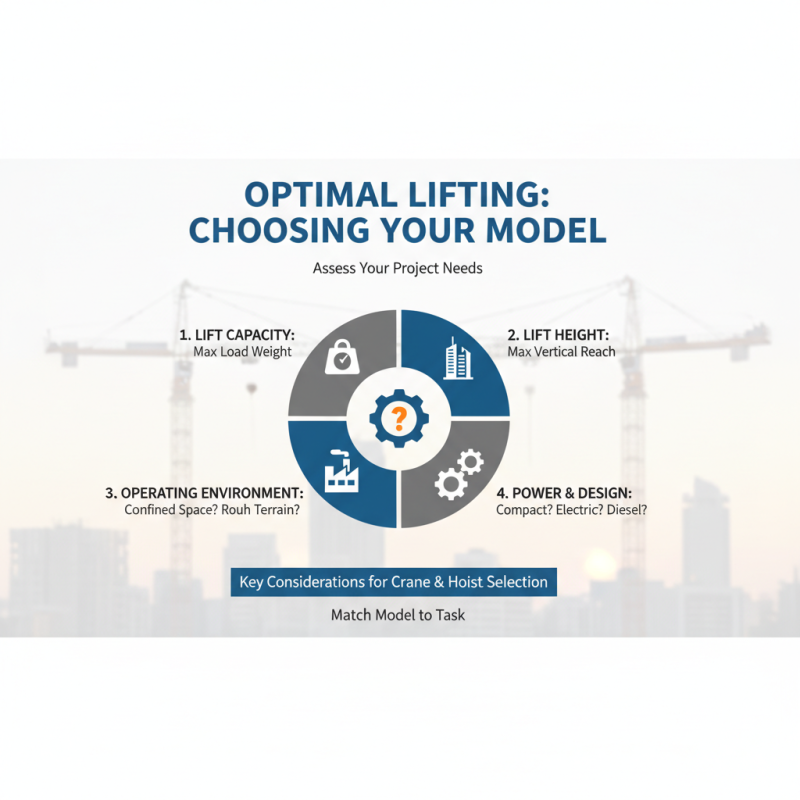

When selecting the right model for your lifting needs, it is essential to first assess your specific requirements. Different projects may demand various lifting capacities, heights, and types of operational environments. For instance, if you're working in a confined space, you might prioritize cranes that offer a compact design without sacrificing power. Understanding the weight of the loads you need to lift will also help determine the maximum lifting capacity necessary for your operations.

Tips: Always evaluate the height range you need for your tasks. Consider whether the crane needs to operate indoors or outdoors, as environmental factors can influence your choice. Additionally, factor in the frequency of use—if you need a crane for continuous lifting, investing in a model designed for heavy-duty performance is crucial.

Another vital aspect is the ease of operation and maintenance. Choose a model that not only meets your lifting requirements but also supports ease of use for your team. User-friendly controls and routine maintenance access can save you time and money in the long run. Engaging with your crew about their preferences and experiences can further guide you towards a model that meets practical operational needs.

When selecting the right model for your Mcdal crane needs, understanding the critical features and specifications is essential. Notably, payload capacity, boom length, and lift height are among the primary specifications that profoundly impact crane performance. According to industry reports, cranes typically range from 1 to 300 tons in capacity, and selecting a model that aligns with the project requirements can greatly enhance efficiency and safety on the job site. Additionally, a longer boom length can extend the reach of the crane, allowing for operations in a wider range, which is particularly beneficial in construction projects involving high-rise buildings or expansive sites.

Another vital aspect to consider is the type of power source. Hydraulic cranes are known for their superior lifting capabilities, while electric cranes can offer a more environmentally friendly operation. Reports indicate that hydraulic cranes account for approximately 60% of the global crane market, owing to their versatility and power. Other specifications, such as mobility features—whether the crane is portable or fixed—should also be evaluated based on the specific needs of your projects. Understanding these key features not only aids in selecting the optimal model but also ensures compliance with safety regulations and enhances operational productivity.

| Model | Load Capacity (tons) | Max Height (m) | Swing Radius (m) | Weight (kg) | Power Source | Special Features |

|---|---|---|---|---|---|---|

| Model A | 10 | 18 | 2.5 | 5000 | Electric | Remote Control |

| Model B | 15 | 20 | 3.0 | 6500 | Diesel | All Terrain |

| Model C | 20 | 25 | 3.5 | 8000 | Electric | High Stability |

| Model D | 25 | 30 | 4.0 | 9000 | Hybrid | Advanced Safety Features |

When selecting the right model for your Mcdal crane needs, considering your budget and overall cost-effectiveness is crucial. The first step in this process is to assess the full extent of your project’s requirements. This includes evaluating the load capacity, working height, and operational environment of the crane. By establishing a clear understanding of these requirements, you can make informed decisions on models that not only meet your operational needs but also align with your financial constraints.

Cost-effectiveness goes beyond just the initial purchase price of the crane. It is essential to consider long-term operational costs, such as maintenance, fuel consumption, and potential downtime during operations. A model that appears cheaper upfront may incur higher costs in the long run if it is not durable or efficient. Therefore, conducting a comprehensive cost-benefit analysis can help you identify models that provide the best value over their lifespan. Additionally, exploring financing options or leasing arrangements can further enhance budget flexibility, enabling you to invest in a crane that balances performance with affordability.

When considering the purchase of Mcdal cranes, consulting with industry experts is essential for obtaining tailored recommendations that meet specific operational needs. Experts can leverage their extensive knowledge of the crane market, including the latest technological advancements and industry standards, to guide buyers towards the most suitable models. According to a report by the International Cranes and Specialized Transport (ICST), 70% of companies that seek expert advice report an improvement in operational efficiency and safety post-implementation. This highlights the importance of expert consultation in ensuring that the chosen crane not only fits current requirements but also accommodates future growth and specialized applications.

A tailored consultation process often involves an assessment of the unique challenges faced by a company. For instance, factors such as load capacity, working environment, and frequency of use play critical roles in determining the right Mcdal crane model. Additionally, experts can provide insights into the latest market trends, including the increasing demand for energy-efficient and environmentally friendly machinery. The World Construction Report indicates that the crane market is projected to grow by 4.4% annually through 2025, further emphasizing the significance of making informed decisions with professional guidance to stay competitive in the evolving landscape. By collaborating with knowledgeable consultants, companies can optimize their crane selection process, ultimately enhancing productivity and reducing operational costs.