The construction industry is experiencing significant growth, with the global construction market projected to reach approximately $15 trillion by 2025, according to a report by Research and Markets. This surge emphasizes the critical need for effective transportation and lifting solutions on construction sites. The efficient use of vehicles and equipment such as trucks and cranes plays a pivotal role in optimizing workflows, ensuring safety, and adhering to project timelines. In fact, industry experts note that proper selection of the right truck and crane can improve operational efficiency by as much as 20%, significantly reducing project costs and timelines.

When choosing the right truck and crane for your construction needs, it is essential to consider factors such as load capacity, reach, maneuverability, and operational requirements. For instance, the maximum load capacity required for specific tasks can vary greatly depending on the project scale and material types involved. Moreover, advancements in technology have enhanced the capabilities of modern trucks and cranes, providing features such as automated controls and improved fuel efficiency, which can further impact the decision-making process. By understanding these crucial elements and leveraging industry data, construction professionals can make informed choices that align with their project demands and optimize productivity.

When selecting the appropriate truck and crane for construction projects, it's essential to understand the various types available and their specific functions. Trucks used in construction come in several forms, including flatbeds, dump trucks, and concrete mixers. Flatbed trucks are often employed to transport heavy materials, while dump trucks are designed for loading and unloading substrate like gravel or soil quickly. Each truck type is tailored to particular tasks, and choosing the right one can significantly affect efficiency on-site.

Cranes are equally important in construction operations, with several designs catering to different needs. Mobile cranes are versatile and can be easily relocated, making them ideal for projects with varying layouts. Tower cranes, on the other hand, are typically fixed and provide the height and lifting capacity needed for tall structures. Another option, the crawler crane, has track-based mobility, allowing it to navigate rough terrains. Understanding these different types of trucks and cranes, along with their specific capabilities, will ensure optimal performance and safety on the construction site.

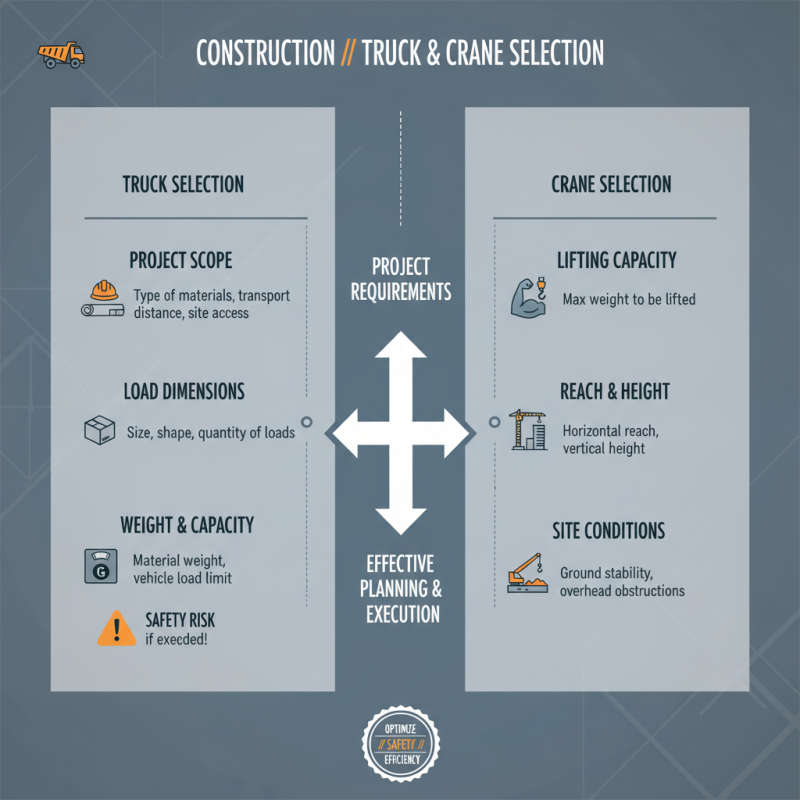

When selecting the appropriate truck and crane for a construction project, assessing project requirements and load specifications is essential for effective planning and execution. Start by clearly defining the scope of the project, including the type of materials to be transported and the dimensions of the loads. This information will influence the choice of vehicle size, lifting capacity, and reach required. Consider the weight of the materials, as exceeding the load limit can pose significant safety risks and lead to project delays.

Additionally, understanding the operating environment is crucial. Analyze site accessibility, terrain conditions, and space constraints before making a decision. If the project involves lifting heavy equipment or oversized materials, a crane with an adaptable reach and adequate lifting power is necessary. Conversely, if the project primarily requires transporting materials over short distances, a reliable truck with appropriate payload capacity may suffice. Combining this knowledge helps ensure that both the truck and crane work harmoniously to meet the demands of the project, promoting efficiency and safety in construction operations.

When selecting a truck for construction tasks, several key factors should be considered to ensure that it meets the specific demands of your project. First and foremost, assess the payload capacity of the truck. Construction jobs often require transporting heavy materials, equipment, and tools, so it's essential to choose a truck that can handle the required weight without compromising safety or performance. Additionally, consider the truck's size and maneuverability. Tight job sites may necessitate a smaller, more agile vehicle, while larger sites may benefit from a bigger truck that can accommodate substantial loads.

Another critical factor is the truck's durability and build quality. Construction environments can be harsh, with exposure to various weather conditions and rugged terrain. A robust truck built with high-quality materials can withstand these challenges, leading to lower maintenance costs over time. Finally, examine the fuel efficiency of the truck as well. Construction projects often involve extensive travel, and a fuel-efficient model can significantly reduce operating costs, ensuring that your investment pays off in the long run. By carefully evaluating these factors, you can select a truck that aligns with your construction needs and enhances overall project efficiency.

| Factor | Description | Importance Level |

|---|---|---|

| Load Capacity | The maximum weight that the truck or crane can safely lift. | High |

| Height Reach | The maximum vertical height that a crane can reach for lifting materials. | Medium |

| Stability | How well the truck or crane maintains its balance while in operation. | High |

| Maneuverability | The ease with which the truck or crane can navigate in tight spaces. | Medium |

| Fuel Efficiency | The amount of fuel consumed relative to the work performed, affecting operational costs. | Low |

| Maintenance Requirements | Frequency and type of maintenance required to keep the truck or crane operational. | Medium |

When selecting cranes for construction projects, safety should be the foremost priority. According to a report from the Occupational Safety and Health Administration (OSHA), crane-related incidents contributed to 22% of all construction worker fatalities between 2011 and 2019. Thus, understanding the essential features that enhance operational safety is critical.

One of the most important features to consider is the crane's load capacity, which should match the specific demands of your project. An in-depth analysis of past construction accidents indicates that many were caused by overloading cranes, underscoring the significance of adhering to the manufacturer's specifications. Furthermore, features such as stability systems, outriggers, and boom length should also be evaluated. Cranes equipped with advanced stability monitoring systems significantly reduce the risk of tipping, especially when working on uneven terrain or in confined spaces.

Additionally, the visibility and control systems of cranes are crucial for ensuring safe operations. Enhanced visibility aids operators in gaining a better view of the load and surrounding site, helping to mitigate potential hazards. Moreover, incorporating technology such as remote controls and smart sensors can further improve operational safety. A survey by the International Cranes and Specialized Transport Association found that 65% of construction companies are gradually adopting smart technologies to enhance safety measures related to crane operation. Ultimately, prioritizing these features can lead to safer and more efficient construction processes.

When selecting the right truck and crane for your construction needs,

cost-effectiveness and maintenance should be at the forefront of your decision-making process. Analyzing the initial purchase price alongside

expected operational costs can provide better insight into the longevity of your investment.

Consider not just the upfront expenses but also factors such as fuel efficiency, repair costs, and the

availability of spare parts. A truck or crane that appears cheaper at first might incur hidden costs

over time that could outweigh the initial savings.

Maintenance considerations are equally crucial, as they directly influence downtime and productivity.

Regular maintenance not only prolongs the life of your equipment but also ensures safety on the job site.

When evaluating options, look for models that are known for their durability and have a solid reputation

for reliable service. Furthermore, consider the ease of maintenance procedures—access to components and

the availability of service providers can significantly affect how quickly you can get equipment back in

working order.

Prioritizing both cost-effectiveness and maintenance capabilities

will lead to more informed, sustainable equipment choices that align with your construction company's needs.