In the construction and heavy machinery industries, large hydraulic cranes have emerged as indispensable assets, integral to the execution of complex lifting operations. These powerful machines leverage hydraulics to enable the movement of substantial loads, with capabilities often exceeding hundreds of tons. According to a report by the International Institute of Crane and Lifting Equipment, the demand for large hydraulic cranes is projected to grow at a substantial rate of around 6% annually through 2030, driven by increasing infrastructure development worldwide and the burgeoning renewable energy sector.

Large hydraulic cranes are characterized by their robust structures and remarkable lifting capacities. They are engineered to perform tasks that require precision and reliability, making them a preferred choice in various sectors, including construction, oil and gas, and shipping. The versatility of large hydraulic cranes allows them to adapt to different environments and lifting challenges, ensuring they can meet the rigorous demands of large-scale projects. With advancements in hydraulic technology and design, these cranes are becoming more efficient, offering improved operational capabilities while ensuring safety and compliance with stringent industry standards. Through this exploration, we will delve into the key features of large hydraulic cranes and their diverse applications across various sectors.

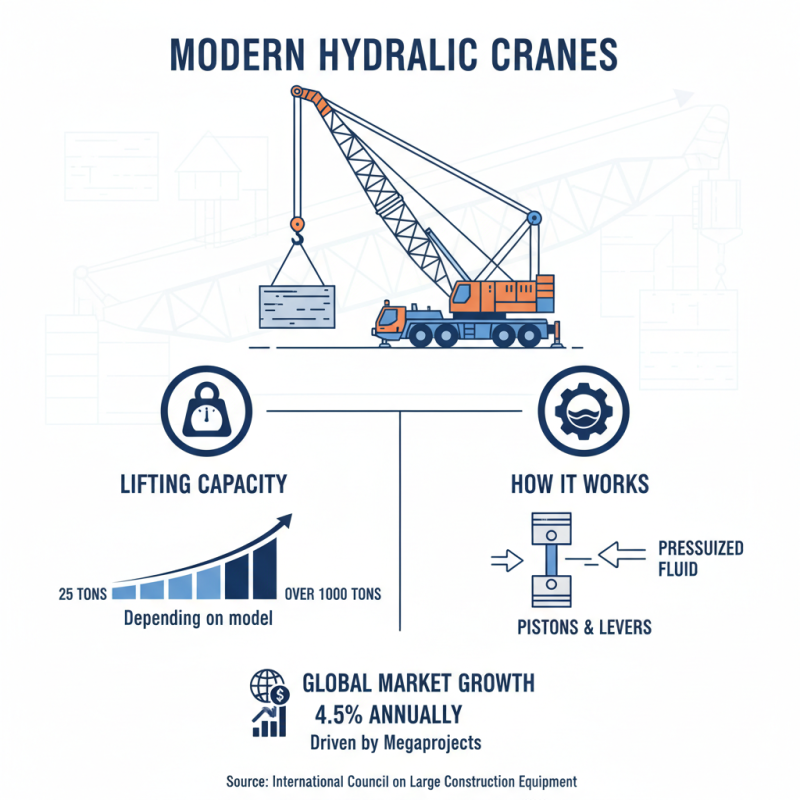

In modern construction, large hydraulic cranes are defined by their capacity to handle substantial loads and their versatility on various construction sites. Typically, these cranes can lift weights ranging from 25 tons to over 1,000 tons, depending on the model and design specifics. This significant lifting capability stems from hydraulic systems that use pressurized fluid to operate pistons and levers, allowing for both vertical and horizontal movements. According to a report from the International Council on Large Construction Equipment, the global market for hydraulic cranes is projected to grow by 4.5% annually, driven by the ever-increasing demand for heavy lifting solutions in megaprojects worldwide.

One distinguishing feature of large hydraulic cranes is their reach. Many models can extend their boom to heights exceeding 200 feet, which is critical in urban construction where space is often limited. Additionally, these cranes are equipped with advanced safety features, including load moment indicators and automated stability systems that prevent tipping during operations. The American Society of Civil Engineers (ASCE) highlights the importance of such innovations, noting that they significantly enhance operational safety and efficiency, allowing for quicker project completions while minimizing risks to workers and surrounding infrastructures. As construction demands evolve, the adaptability of large hydraulic cranes continues to play a vital role in enabling complex and ambitious projects across various sectors.

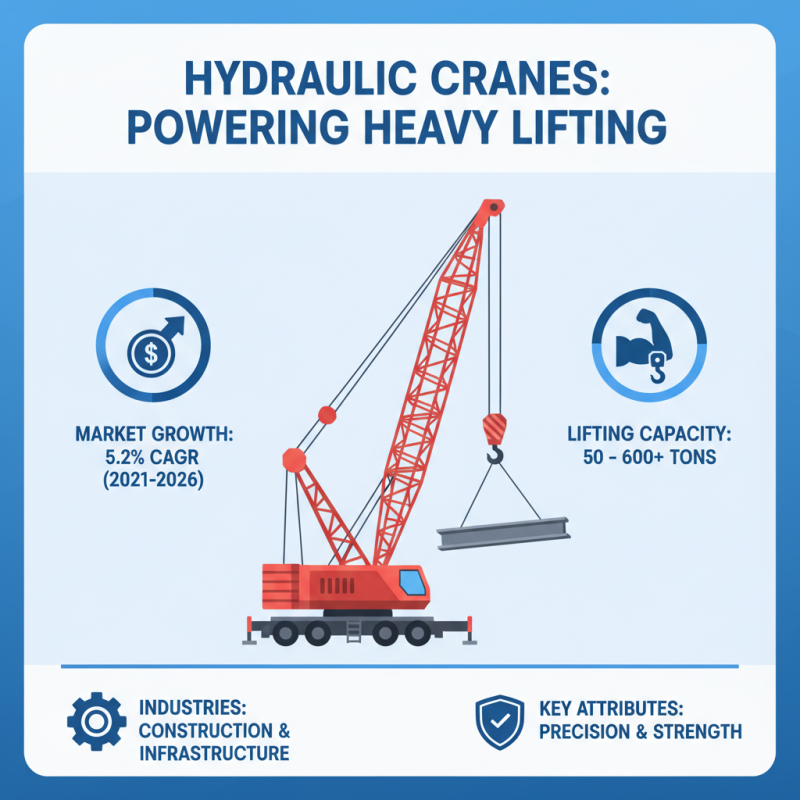

Large hydraulic cranes are vital in industries requiring heavy lifting capabilities, providing unmatched precision and strength. A key technical specification to consider when evaluating hydraulic cranes is their lifting capacity, which can range from 50 tons to over 600 tons, depending on the model and design. For instance, studies reveal that the global hydraulic crane market is projected to grow at a CAGR of 5.2% from 2021 to 2026, driven by increasing demand in construction and infrastructure projects.

Performance metrics such as boom length and hydraulic system pressure are crucial indicators of a crane's efficiency. Typical boom lengths for large hydraulic cranes can reach upwards of 240 feet, enabling them to lift heavy loads at significant distances. Moreover, many hydraulic cranes operate at pressures between 3,000 and 6,000 psi, allowing for smooth and controlled operation under heavy stress conditions. Industry reports suggest that cranes with advanced hydraulic systems not only enhance lifting performance but also improve safety measures, directly affecting project timelines and overall productivity.

In addition, the operational versatility offered by large hydraulic cranes makes them suitable for diverse applications, from construction to shipbuilding and oil and gas exploration. Their ability to perform in varied environments underscores the importance of adhering to stringent safety standards, as highlighted in compliance reports from leading safety organizations, ensuring that operators can maximize efficiency while minimizing risks.

Large hydraulic cranes are marvels of engineering, designed to handle substantial loads with precision and efficiency. These cranes typically feature impressive load capacities that can range from 50 tons to over 1,000 tons, depending on their design and application. The hydraulic system allows for smooth lifting and lowering of massive weights, enabling the cranes to perform tasks that would be impossible with traditional mechanical systems. This capability makes them invaluable in sectors such as construction, shipping, and heavy manufacturing.

In terms of lifting heights, large hydraulic cranes can generally reach anywhere from 30 meters to over 100 meters, depending on their configuration and the specific model. This versatility is crucial for projects that require elevation, such as installing large structural components or lifting materials high above ground level. With their exceptional load capacity and height capabilities, large hydraulic cranes play a vital role in efficiently completing complex projects, ensuring safety and reliability in heavy lifting operations.

Large hydraulic cranes are versatile machines widely utilized across various industries due to their powerful lifting capabilities and innovative features. In the construction sector, they are essential for lifting heavy materials such as steel beams, concrete panels, and prefabricated structures. These cranes can easily handle significant loads, making them invaluable on large job sites where cranes are frequently employed to assemble high-rise buildings and infrastructure projects. Their ability to reach considerable heights and extend over considerable distances allows them to efficiently place materials exactly where needed.

In the manufacturing and industrial sectors, large hydraulic cranes play a critical role in moving heavy machinery and equipment during assembly and maintenance processes. These cranes help streamline operations by facilitating the transportation of large components from one area to another, thus increasing productivity. Furthermore, in the shipping industry, they are used for loading and unloading cargo containers from ships, providing a vital link in the supply chain. Their adaptability and strength make large hydraulic cranes an indispensable asset across various applications, enhancing efficiency and safety in heavy lifting operations.

When it comes to large hydraulic cranes, safety standards and regulations play a crucial role in ensuring their effective and responsible use across various industries. According to the Occupational Safety and Health Administration (OSHA), operators of hydraulic cranes must adhere to strict guidelines that dictate everything from equipment testing to operator certification. These regulations are crucial in minimizing the risks associated with crane operations, which are among the most hazardous activities in construction and heavy lifting sectors.

In addition to OSHA standards, the American National Standards Institute (ANSI) provides comprehensive guidelines that help establish a framework for the safe use of hydraulic cranes. These standards cover aspects such as load limits, inspection protocols, and operator training requirements. A report by the International Organization for Standardization (ISO) indicates that compliance with these safety standards can reduce crane-related accidents by as much as 30%. As large hydraulic cranes are commonly utilized in situations where heavy loads are involved, ensuring adherence to these rigorous safety regulations not only protects operators but also safeguards the general public and adjacent workers.

It is vital for companies in the construction and manufacturing sectors to implement robust safety management systems that align with these regulatory expectations. By doing so, organizations can mitigate risks associated with crane operations, improve operational efficiency, and reinforce their commitment to workplace safety. Regular training sessions and adherence to inspection schedules are essential in cultivating a safety-first culture that prioritizes compliance with existing safety standards and regulations governing hydraulic cranes.