In the construction and heavy lifting industries, the significance of proper crane rigging cannot be overstated. According to the Occupational Safety and Health Administration (OSHA), inadequate rigging and improper lifting procedures are contributing factors in approximately 40% of crane-related incidents. These staggering statistics highlight the urgency of establishing comprehensive safety protocols for lifting operations, emphasizing the critical nature of effective crane rigging methods.

Expert opinions in the field underline the importance of rigorous training and adherence to safety standards. For instance, renowned crane safety specialist John Smith states, “The foundation of safe lifting operations lies in meticulous crane rigging practices; one lapse can lead to catastrophic outcomes.” This insight encapsulates the essence of the industry’s commitment to safety, reiterating that thorough knowledge and application of crane rigging techniques safeguard lives, equipment, and projects.

As the industry evolves, continuous education and innovation are paramount to reducing accidents related to crane operations. By prioritizing proper crane rigging, companies not only comply with safety regulations but also foster a culture of safety that permeates their operations. In this light, the discussion surrounding crane rigging must remain at the forefront of industry conversations, ensuring that safety remains a collective priority.

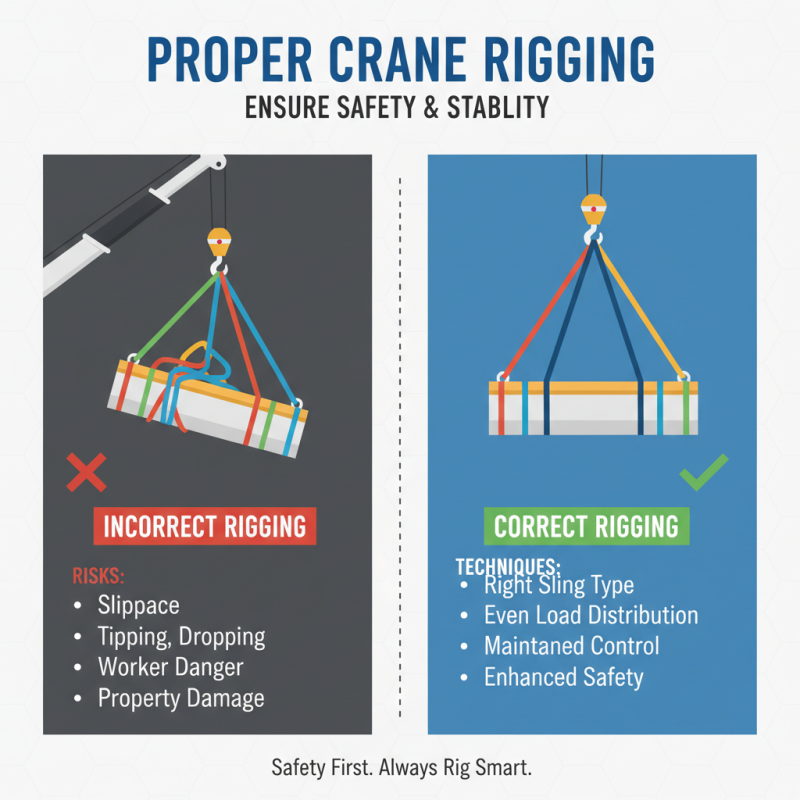

Proper crane rigging is crucial for ensuring load stability during lifting operations. When loads are rigged incorrectly, the risk of slippage, tipping, or dropping increases significantly. This not only jeopardizes the safety of the workers involved but also poses a danger to nearby personnel and property. By employing the correct rigging techniques, such as choosing the right sling type and ensuring even load distribution, operators can maintain control over the load throughout the lifting process.

Additionally, the stability of the load is directly influenced by the rigging equipment used. High-quality rigging hardware, when properly utilized, minimizes the chances of failure. Regular inspections and adherence to weight limits are essential practices that enhance load stability. Understanding the dynamics of lifting operations, including factors like load center of gravity and environmental conditions, allows crews to plan effectively and mitigate potential hazards. Such proactive measures are vital in maintaining a safe work environment and ensuring the success of lifting operations.

Proper crane rigging is crucial in ensuring the safety and efficiency of lifting operations. Understanding key components of crane rigging is essential for workers to prevent accidents and equipment failures. One of the primary elements in crane rigging is the selection of appropriate rigging equipment, such as slings, shackles, and hooks. Each component must be rated for the specific load limits and environmental conditions they will encounter during operation. For instance, synthetic slings are lightweight and flexible, while wire rope slings offer durability and strength for heavier loads. Ensuring that these components are well-maintained and inspected regularly is vital to maintaining safety standards.

In addition to equipment, the techniques employed in crane rigging play a significant role in the success of lifting tasks. Proper rigging techniques involve correct load balancing, which minimizes the risk of tipping or swinging during lifts. Operators should be trained in various hitch configurations, such as the vertical hitch, choke hitch, and basket hitch, as each is suited for different types of loads. Furthermore, coordinating movements between the crane operator and ground personnel helps in executing lifts smoothly, reducing the chances of accidents. By mastering both the equipment and techniques of crane rigging, teams can significantly enhance lifting safety and operational efficiency.

Proper crane rigging is crucial for ensuring safety during lifting operations, and industry standards and regulations play a significant role in shaping these practices. Organizations such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) have established comprehensive guidelines that dictate the proper techniques for rigging equipment. These standards cover various aspects, including the selection of rigging hardware, load calculations, and inspection protocols, all aimed at minimizing risks associated with lifting heavy loads.

Compliance with these regulations is not simply a matter of legal obligation but is essential for protecting workers and equipment. The standards require training and competency assessments for riggers to ensure that personnel have the necessary skills to identify hazards and execute safe lifting practices. Additionally, regular inspections of rigging equipment are mandated to ensure that it remains in good condition, thereby reducing the likelihood of accidents caused by equipment failure. By following established industry standards, companies can foster a culture of safety that prioritizes consistent adherence to best practices in crane rigging.

| Data Dimension | Description | Industry Standard/Regulation |

|---|---|---|

| Load Capacity | The maximum load that a crane can lift safely. | ANSI/ASME B30.5 |

| Rigging Inspection | Regular checks to ensure that rigging equipment is in safe working condition. | OSHA 1926.251 |

| Operator Qualifications | Training and certification requirements for crane operators. | OSHA 1910.178 |

| Weight Distribution | Guidelines for evenly distributing the weight of the load to prevent tipping. | Crane Manufacturer's Guidelines |

| Tag Lines | Using tag lines to control the load and prevent swing during lifting operations. | National Standards |

| Weather Conditions | Considerations for lifting operations in adverse weather conditions. | OSHA 1926.1400 |

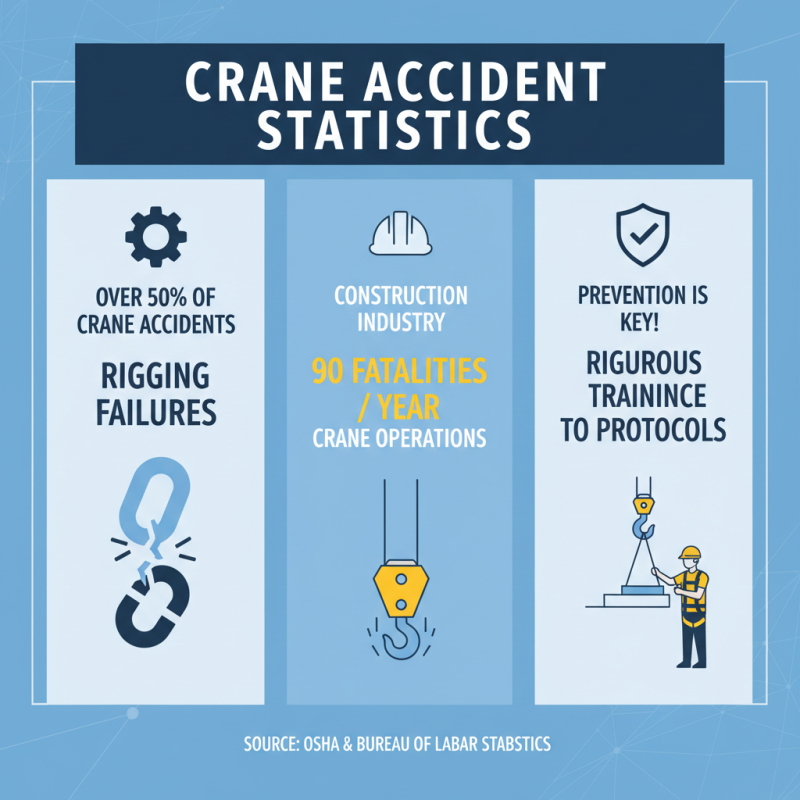

Improper rigging procedures are a significant contributor to crane-related accidents, making it crucial to understand the statistics behind these incidents. According to the Occupational Safety and Health Administration (OSHA), over 50% of all crane accidents are attributed to rigging failures. In a report from the Bureau of Labor Statistics, it was found that the construction industry, in particular, sees approximately 90 fatalities each year related to crane operations, with many directly tied to inadequate rigging practices. These alarming numbers underscore the need for rigorous training and adherence to proper rigging protocols to safeguard workers and the general public.

Furthermore, a study conducted by the National Council for Occupational Safety and Health highlights that nearly 25% of crane accidents occur due to insufficient rigging knowledge among operators and riggers. This reinforces the imperative for ongoing education and certification in crane operations, as many accidents could be prevented through proper training. In light of these findings, implementing comprehensive safety programs that emphasize the importance of correct rigging methods can drastically reduce the number of accidents, thereby enhancing overall safety in lifting operations. The evidence clearly illustrates that when rigging is neglected, the consequences can be devastating, making proper crane rigging not just essential but vital for operational safety.

Proper crane rigging is paramount to ensure the safety and efficiency of lifting operations. Training and certification requirements for riggers are crucial components in achieving this safety. Workers involved in crane operations must undergo rigorous training that encompasses understanding load dynamics, rigging techniques, and safety protocols. Courses typically cover the selection of appropriate rigging gear, the calculation of load weights, and the identification of potential hazards that may arise during lifting tasks.

Certification programs often require practical assessments, ensuring that the riggers not only comprehend theoretical knowledge but can also apply it effectively on the job site. These certifications help establish a benchmark for competency, giving employers confidence in their workers' capabilities. Additionally, ongoing training updates and recertification are essential as standards and technologies in crane operations evolve. By investing in comprehensive training and adherence to certification requirements, organizations can significantly mitigate risks and enhance the overall safety of crane lifting operations.