Choosing the right equipment is crucial for any construction project. The largest truck crane can significantly impact efficiency and safety. John Smith, an industry expert from Crane Innovations, once stated, “Selecting the right crane is as vital as understanding the project’s needs.”

When you consider the largest truck crane, think of its capacity. The load-bearing ability often determines project feasibility. However, size alone isn't the only factor. Gathering project specifics is just as essential.

Moreover, oversizing can lead to complications. It may increase costs unnecessarily and complicate operation. Each project has unique requirements that must align with equipment choices. Proper evaluation is key to avoiding pitfalls and ensuring successful outcomes.

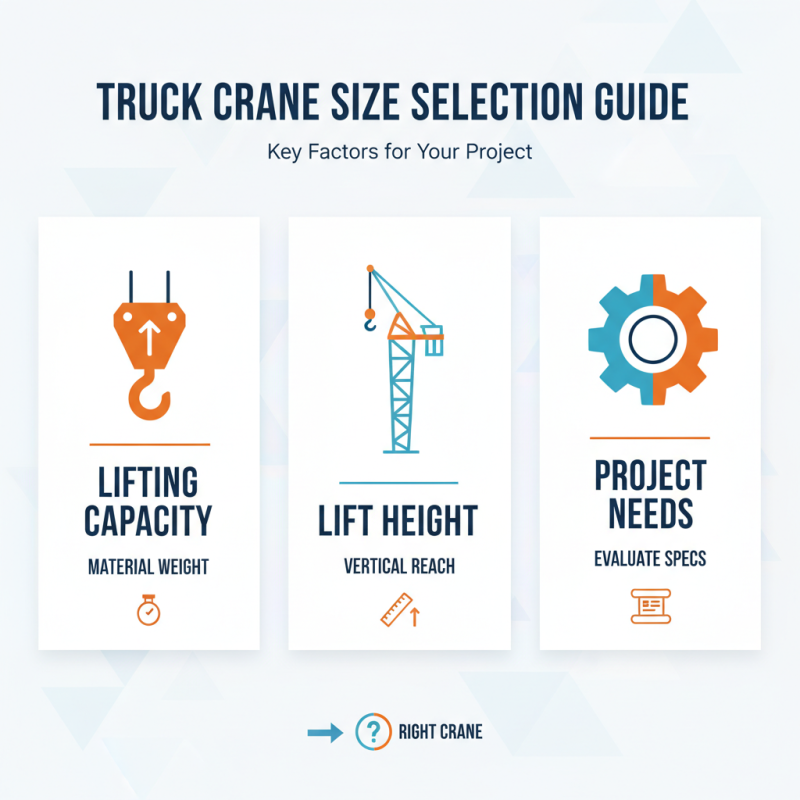

When selecting the right truck crane size, several factors come into play. Understanding your project's requirements is crucial. Lifting capacity is one major aspect. Evaluate the weight of the materials you'll be lifting. This will guide you toward the right crane size. Consider the height you need to lift as well. Not all projects have the same vertical demands.

You should also assess the worksite conditions. Space limitations can affect your choice. If the area is confined, a larger crane may not be feasible. Stability is another factor that shouldn’t be overlooked. A larger crane generally provides more stability, but it needs enough space to operate safely. Reflect on how terrain may influence your decision as well. Uneven or soft ground might not support larger models without additional precautions.

Ultimately, it's about balancing needs with realistic capabilities. Sometimes, opting for a larger crane seems ideal, but operational constraints can complicate this. The goal is to find a crane that meets your demands while ensuring safety and efficiency. Being mindful of these elements can lead to better choices and project outcomes.

Selecting the right truck crane is crucial for project efficiency. Understanding load capacity is fundamental. Load capacity determines how much weight a crane can safely lift. It's essential to consider the weight of materials and equipment, along with the crane's limits. Data shows that overloading a crane can lead to accidents. Accidents increase project delays and costs.

Many projects underestimate load requirements. A survey by the Crane Institute indicates that 35% of project delays stem from equipment failure due to improper load calculations. Ensure your crane meets and exceeds the projected load. The right crane can increase efficiency by 20% or more. That means finishing projects quicker and minimizing labor costs.

Evaluate site conditions, too. Some areas have strict weight restrictions. Local regulations may limit crane size or load. These can significantly affect your project timeline. Assess ground stability and space availability. Cranes need a substantial footprint, so plan accordingly. Remember, not all projects are the same. Each project may require a unique approach to meet its specific load and operational challenges.

When considering a truck crane for your project, boom length is a crucial factor. The reach of the crane will determine its efficiency and capability. Data from industry reports indicate that a boom length of 40 to 50 feet is common for many construction sites. However, specialized tasks may require larger booms that extend beyond 100 feet.

Tip: Evaluate the maximum reach required for your specific applications before making a decision. Understand the load capacities at different boom lengths. Many cranes can lift heavy loads at shorter spans but struggle as the boom extends. This means a crane that appears to meet your needs may still fall short in performance.

Consider your project layout as well. Obstacles and site conditions can limit usable boom length. Understanding how these factors influence reach options is essential. Reports highlight that around 30% of delays in projects stem from improper assessments of crane capabilities. Proper planning can mitigate these risks.

Tip: Always consult a certified crane operator or engineer. Their insights can guide you in selecting the right crane. They can also advise on potential hazards and safety measures. Often, cranes are underutilized due to poor planning. Make sure your selection aligns with project needs.

When evaluating stability and ground conditions for crane operations, several factors come into play. The ground must support the crane's weight and the load it carries. According to the Occupational Safety and Health Administration (OSHA), about 65% of crane accidents happen due to ground failures. This highlights the importance of proper site evaluation.

Ideal conditions include firm, level ground. Soft soil, mud, or sand can compromise stability. Soil rigidity must be measured. Engineers often recommend soil tests. A simple penetrometer test can predict soil strength. If the soil is weak, measures must be taken. These may involve using mats or reinforcements.

Gauging wind conditions is just as critical. Cranes are sensitive to high winds. The National Institute for Occupational Safety and Health (NIOSH) states that operations should cease when wind speeds exceed 20 mph for most cranes. It’s crucial to monitor real-time weather data. Installing an anemometer on-site can provide up-to-date information. Ignoring these factors can lead to catastrophic failures. A reliable crane operation hinges on a thorough assessment of both ground conditions and weather influences.

| Tip No. | Tip | Importance | Considerations |

|---|---|---|---|

| 1 | Assess Project Weight Requirements | High | Ensure crane capacity exceeds total load |

| 2 | Evaluate Ground Conditions | High | Conduct soil tests; consider load distribution |

| 3 | Confirm Stability Features | Medium | Look for outriggers and counterweights |

| 4 | Check Reach and Height | Medium | Ensure it meets project specifications |

| 5 | Assess Mobility | Low | Consider site layout and access routes |

| 6 | Inspect Safety Features | High | Crane certification and safety protocols |

| 7 | Consider Operator Experience | Medium | Skilled operators for safe operations |

| 8 | Review Rental Options | Low | Evaluate cost and terms of service |

| 9 | Plan Lift Sequence | High | Organize lifts for efficiency and safety |

| 10 | Consult with Professionals | High | Seek expert advice for crane selection |

When considering the cost-effectiveness of truck cranes, various models present different economics. A recent industry report shows that operational costs vary significantly among models. Some truck cranes cost around $250,000, while others exceed $500,000. This initial price is crucial but not the only factor.

Maintenance costs also play a role. Data suggests that cranes with advanced technology can reduce maintenance intervals. Some models promise a 20% reduction in routine repairs, translating into significant savings over time. However, the investment in high-tech features may not always pay off in every project context. If the project lacks demanding requirements, simpler models may suffice.

Fuel efficiency is another key consideration. Trucks averaging 5 miles per gallon can lead to exorbitant fuel costs in extensive projects. However, newer models boast up to 8 miles per gallon. This difference impacts overall cost-effectiveness. Yet, even with improved efficiency, not every project will utilize this advantage fully. Evaluating the specific needs of your project is essential before making a decision.

This chart compares the cost-effectiveness of various truck crane models based on their lifting capacity and operational cost per hour. The selected models are representative of the industry standards.