In the dynamic world of construction, the choice of equipment can significantly impact the efficiency and safety of a project. Among the various tools available, the professional crane is indispensable for lifting and moving heavy materials. Renowned industry expert, John Smith, an engineer with over 20 years of experience in crane operations, emphasizes, “The right professional crane can make all the difference in project execution, reducing time and enhancing precision.” This underscores the crucial role that cranes play in modern construction projects, catering to diverse needs from residential buildings to large-scale infrastructure developments.

Understanding the different types of professional cranes is essential for project managers and contractors looking to optimize their operations. Each crane type boasts unique features tailored to specific tasks, ranging from mobile cranes that provide versatility on job sites to tower cranes that excel in height and reach. By exploring the top ten professional crane types used in construction, we aim to highlight their key characteristics and applications, enabling stakeholders to make informed decisions for their projects. Whether it’s for lifting steel beams or positioning precast components, the right selection of a professional crane can lead to seamless operation and successful project outcomes.

When it comes to construction, cranes are essential for lifting and transporting heavy materials, facilitating various operations on-site. The selection of a crane type depends on the specific requirements of the project, including the size of the load, the height of the lift, and site conditions. Each crane type is designed with unique features that make it suitable for certain tasks.

Tower cranes, for example, are ideal for high-rise construction projects. They offer significant lifting height and radius, allowing them to reach over buildings and transport materials efficiently. On the other hand, mobile cranes, known for their versatility, can be easily relocated around the site and are particularly useful for smaller projects where maneuverability is crucial. Similarly, crawler cranes, equipped with tracks for stability, excel in outdoor environments and heavy-duty lifting.

Additionally, overhead cranes, commonly found in warehouses and manufacturing facilities, provide a solution for lifting materials in a horizontal plane. They are essential for assembly lines and large material handling tasks. Each crane type plays a pivotal role in ensuring that construction projects run smoothly, highlighting the importance of choosing the right crane based on specific project needs.

Mobile cranes are versatile and essential tools in the construction industry, designed to facilitate the lifting and moving of heavy materials across various job sites. One key feature of mobile cranes is their ability to travel on public roads, allowing them to easily reach diverse locations without the need for extensive disassembly. Equipped with telescopic booms or lattice structures, these cranes can extend their reach to handle tall buildings and deep excavations, making them indispensable for many construction projects.

Another significant aspect of mobile cranes is their quick setup and adaptability. With options such as rough terrain and all-terrain cranes, they can operate in challenging environments, from uneven surfaces to restricted spaces. Their advanced hydraulic systems provide precise control over lifting operations, enabling operators to maneuver loads with accuracy and safety. This flexibility, combined with their mobility and efficient operation, makes mobile cranes a preferred choice for contractors aiming to enhance productivity and meet tight deadlines in construction projects.

Tower cranes are revolutionizing high-rise building projects by providing unmatched height and lifting capacity that are essential in modern construction. According to a report from the Global Construction Forecast, the use of tower cranes has increased by approximately 25% in the past five years, making them a staple in urban development. These cranes can reach significant heights, often exceeding 200 meters, which allows for the construction of skyscrapers and large commercial complexes in densely populated areas. Their ability to lift heavy materials—often exceeding 20 tons—enables them to efficiently handle the demands of high-rise construction, significantly reducing project timelines.

One of the key advantages of tower cranes is their versatility. They can be configured for various site conditions and construction phases, which is essential for the dynamic nature of high-rise projects. Additionally, they typically have a smaller footprint compared to other types of cranes, allowing for better space management in tight urban environments. A study by the American Society of Civil Engineers revealed that properly utilized tower cranes can improve logistics and reduce material handling times by up to 30%, showcasing their critical role in enhancing productivity on-site.

**Tips for Effective Tower Crane Use:**

- Ensure careful planning and coordination with contractors to optimize crane positioning and minimize downtime.

- Regularly inspect tower cranes to guarantee safety and compliance with local regulations, reducing the risk of accidents.

- Consider the use of advanced technology, such as load monitoring systems, to enhance operational precision and safety during the lifting process.

| Crane Type | Key Features | Advantages |

|---|---|---|

| Tower Crane | High lifting capacity, fixed to the ground | Ideal for high-rise buildings, stable at great heights |

| Mobile Crane | Versatile, capable of moving around worksites | Flexibility in operations and set up |

| Crawler Crane | Tracks for mobility on difficult terrain | Stability on soft ground, good for heavy lifting |

| Rough Terrain Crane | Designed for off-road conditions | Superior off-road capability, mobility |

| Overhead Crane | Mounted on a frame, spans large areas | Maximizes workspace, efficient lifting |

| Telehandler | Versatile, with a telescoping arm | Can tackle a variety of lifting tasks |

| Floating Crane | Mounted on a barge, suitable for marine work | Ideal for construction over water |

| Luffing Jib Crane | Jib that luffs, reducing swing | Ideal for small sites or complex lifts |

| Bored Pile Crane | Specialized for deep foundation work | Effective for large structures |

Crawler cranes are an essential piece of equipment in heavy lifting operations, particularly in construction projects that require stability and maneuverability on rough terrain. These cranes feature a unique track system that distributes their weight evenly, allowing them to operate safely on soft ground or uneven surfaces. The low ground pressure of crawler cranes prevents damage to the underlying substrate, making them ideal for sites where traditional wheeled cranes might struggle.

One of the standout benefits of crawler cranes is their impressive lifting capacity combined with their ability to move with heavy loads attached. Unlike other crane types, crawler cranes can travel while carrying their maximum load, enhancing productivity and efficiency on the job site. Additionally, they often come equipped with articulating booms or telescopic features that allow for greater reach and flexibility. This versatility enables them to tackle a wide range of lifting tasks, from placing large steel structures to handling sensitive equipment more gracefully, making them a preferred choice for many construction professionals.

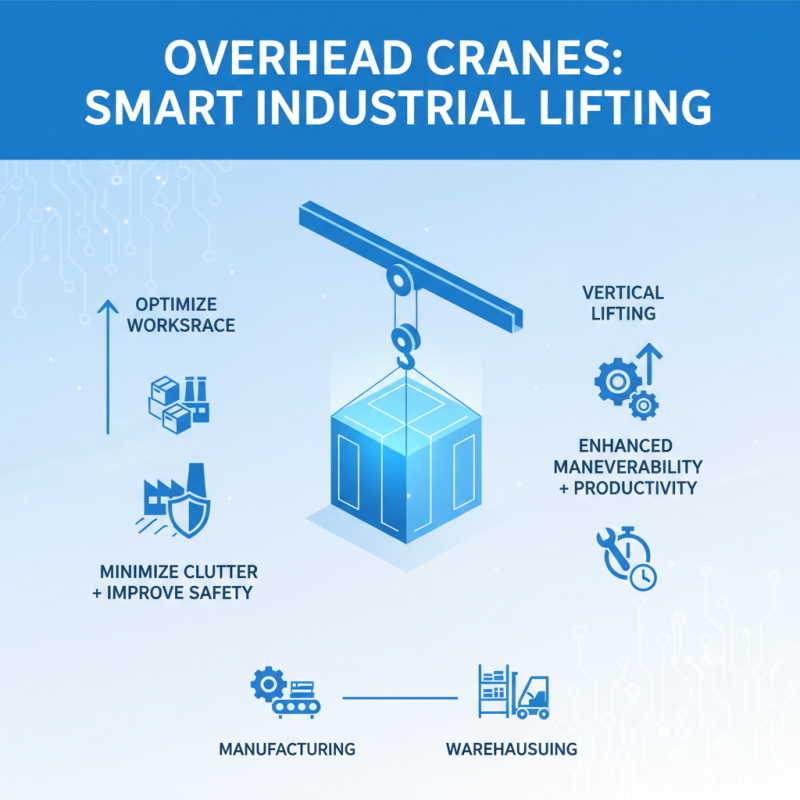

Overhead cranes are an essential component in many industrial settings, providing efficient solutions for lifting and moving heavy materials. One of their most innovative features is the ability to optimize workspace by utilizing the overhead area, thus minimizing ground-level clutter and improving safety. This vertical lifting capability allows for better maneuverability in tight spaces, enabling industries such as manufacturing and warehousing to maximize their productivity.

Moreover, advancements in technology have led to the integration of intelligent systems in overhead cranes. Features such as load monitoring sensors and automated controls enhance the safety and operational efficiency of these cranes. The ability to track load weights in real-time prevents overloading and reduces the risk of accidents. Additionally, programmable controls allow for precise movements and automated lifting sequences, streamlining operations and reducing the need for manual intervention. By enhancing both safety and efficiency, these innovative features make overhead cranes a vital asset in modern industrial environments.